The exceptional electronic properties of graphene make it a material with large potential for low-power, high-frequency electronics. However, the performance of a graphene-based device depends not only on the properties of the graphene itself, but also on the quality of its metal contacts. The lack of effective and manufacturable approaches to establish good ohmic contacts to a graphene sheet is one of the factors that limit today the full application potential of graphene technology.

The quality of the graphene-metal contacts is described in terms of the contact resistance (RC). Low RC values are crucial for any high-frequency or low-power application. Graphene’s low density of states near the charge neutrality point (Dirac point) limits carrier injection from metals, often resulting in high RC values.

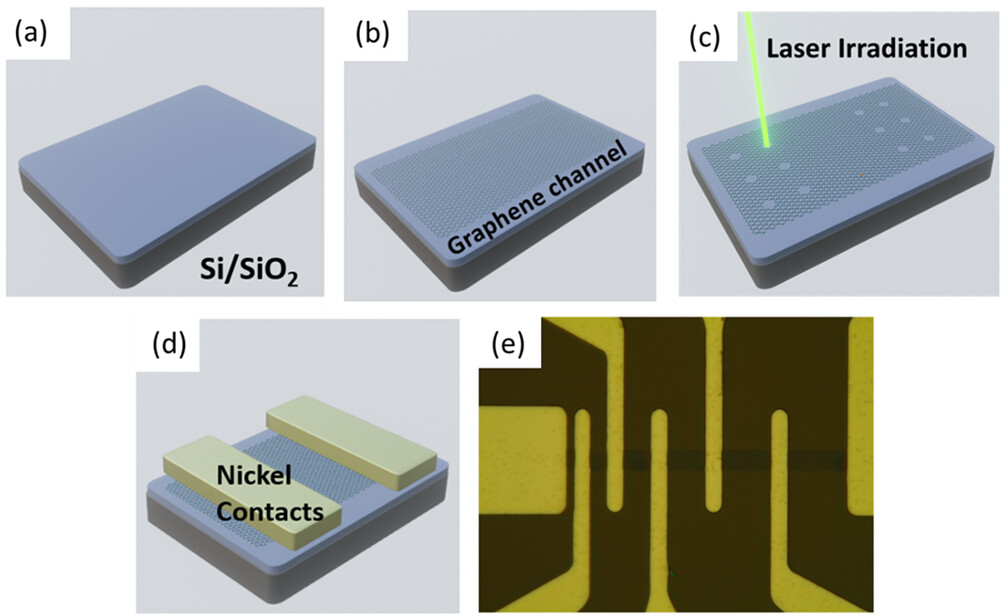

Researchers at the Chair of Electronic Devices (ELD) at RWTH Aachen University and AMO GmbH have shown that RC can be substantially reduced by laser irradiation in the contact region – with a reported reduction of RC up to 70% with respect to untreated devices. This is attributed to an increase in defect density, which leads to the formation of crystallite edges and in-plane dangling bonds that enhance the injection of charge carriers from the metal into the graphene.

The proposed method can be easily scaled, implemented, and automated to engineer the RC in graphene and potentially other 2D material-based devices.

These results have been reported in ACS Applied Electronic Materials.

Bibliographic information

Reducing the metal-graphene contact resistance through laser-induced defects

V. Jangra, S. Kataria, M. C. Lemme

ACS Applied Materials & Interfaces (2024).